Hydrostatic level transmitter – how it works?

In the following article, we discuss the principle of operation and application of hydrostatic probes. In addition, we share practical tips on how to choose the right hydrostatic probe for your application. Read on!

What is hydrostatic pressure?

Hydrostatic pressure is the pressure exerted by a column of liquid, depending on its height and density. In simplest terms, it is the pressure prevailing at a given depth. The greater the depth, the greater the hydrostatic pressure, because the weight of the liquid increases under the influence of a downward force (gravity).

Hydrostatic pressure measurement – paradox

The hydrostatic pressure of a liquid depends only on depth. This parameter is not influenced by the size of the container or its shape. This phenomenon is called the "hydrostatic paradox".

Hydrostatic liquid level measurement in a tank

Hydrostatic probe - principle of operation

Pressure measurement is made at the level of the membrane of the submerged probe and related to atmospheric pressure, which is measured by a capillary tube. This method owes its popularity to its simplicity and high reliability.

Hydrostatic level transmitter – how it works?

What is hydrostatic pressure?

Hydrostatic pressure is the pressure exerted by a column of liquid, depending on its height and density. In simplest terms, it is the pressure prevailing at a given depth. The greater the depth, the greater the hydrostatic pressure, because the weight of the liquid increases under the influence of a downward force (gravity).

Hydrostatic pressure measurement – paradox

The hydrostatic pressure of a liquid depends only on depth. This parameter is not influenced by the size of the container or its shape. This phenomenon is called the "hydrostatic paradox".

Hydrostatic level measurement of a liquid in a tank

What is hydrostatic level transmitter?

Hydrostatic level sensor is submersible pressure transmitter. It is used to monitor liquid levels by measuring hydrostatic pressure.

How does a water level sensor work?

Pressure is measured at the level of the probe's submerged diaphragm and related to atmospheric pressure, which is measured through a capillary tube. This method owes its popularity to its simplicity and high reliability.

Hydrostatic level sensor commonly compensates for the atmospheric pressure changes automatically, so the pressure measured represents only the pressure of the liquid due to the specific gravity of the liquid and the vertical distance to the surface.

Application of hydrostatic level transmitter

This measurement method is widely used in various industries including food and water and wastewater – in wastewater treatment plants and pumping stations. Depending on the application, we distinguish between such hydrostatic probes as:

Hydrostatic level sensor for wastewater

e.g. JUMO MAERA F27 hydrostatic level sensor for wastewater

Hydrostatic level transmitter for water

e.g. hydrostatic level sensor 4 20 mA JUMO MAERA S25

Hydrostatic level sensor for wells

e.g. hydrostatic level sensor for drinking water JUMO MAERA S28

How does hydrostatic level measurement work?

A hydrostatic level measurement uses a hydrostatic probe. It is mounted or lowered to a specific depth (zero level). The water pressure sensor, due to the hydrostatic paradox, does not measure the entire volume of the tank, but only the vertical column of liquid directly above it. If the specific gravity of the liquid is known, the pressure value can be calculated as the distance from the zero level, where the transducer is located, to the liquid surface.

What is an advantage of a hydrostatic level?

-

high reliability

-

high accuracy level monitoring

-

direct contact with the medium

-

measurement processes are not affected by factors such as contamination, foam etc. – suitable for foaming or vessel installations

Water level pressure transducers – additional features

Level pressure transducer make it possible to measure not only the current level value, but also to monitor changes in level from an arbitrary reference point within the medium (continuous liquid level monitoring).

What is more, because submersible hydrostatic level transmitter is mounted below the surface of the water, they are totally unaffected by any disturbance to the water surface, such as flooding.

How do I choose the right pressure liquid level sensor?

For open tanks, such as vent vessels, wells or natural or artificial water reservoirs, use submersible pressure transmitters called level probes. For closed tanks, submersible pressure sensors with a flush diaphragm or transmitters that can be screwed onto the tank from the outside will be most suitable.

Once you have made this decision, identify these few key features:

-

pressure connection (only if it is a standard side-mounted transducer) – to fit the threaded hole in the tank.

-

measuring range – this should be selected to suit the level to be measured in the application. In the case of a free-standing tank, the level is determined by its height. In an underground tank, you need to decide at what depth you want to immerse the level probe and select the appropriate measuring range. Note that 10 metres of water column corresponds to a pressure of approximately 1,000 mbar (1 bar) or 14.5 psi.

-

accuracy – a standard accuracy of <0.5% gives a possible error of max. 5 mm per metre of level, while variants with the highest accuracy of <0.1% will have an accuracy of max. 1 mm per metre of level.

-

electrical connection – in a standard sensor you can choose either a connector (such as M12 or DIN A) or a cable outlet, whereas if you have chosen a submersible water pressure sensor, only a cable is an available option.

In the case of a cable connector, you will need to select the correct length to allow the cable from the transducer to the control system and, in the case of a submersible sensor, to be at the correct depth.

-

material of construction – as standard, the level sensors are made of stainless steel, such as the JUMO MAERA S 28, however, for demanding media we recommend a resistant liquid level sensor ps made of titanium, e.g. the JUMO MAERA S 29 hydrostatic probe.

-

additional functions, e.g. ex-zone approval, as in the JUMO dTRANS p33 hydrostatic probe.

Hydrostatic level measurement – temperature compensation

If the temperature of a liquid increases, it will increase in volume, causing the liquid level to rise. This phenomenon has a negative effect on the accuracy of the measurement results. However, if precise hydrostatic level measurement is required at varying fluid temperatures, then, in order to prevent errors due to temperature influence, we recommend fitting a simple and economical additional sensor such as a Pt100 temperature probe.

Alternatively, you can choose a hydrostatic level sensor with an integrated sensor for temperature measurement, such as the JUMO MAERA F27.

JUMO liquid level sensors

JUMO offers a wide range of hydrostatic sensors for the continuous monitoring of liquid levels. Contact us – our specialists will select a device for your application.

Hydrostatic level measurement is used, among others, in the food industry

How does hydrostatic level measurement work?

A hydrostatic level measurement uses a hydrostatic probe. It is mounted or lowered to a specific depth (zero level). The water pressure sensor, due to the hydrostatic paradox, does not measure the entire volume of the tank, but only the vertical column of liquid directly above it. If the specific gravity of the liquid is known, the pressure value can be calculated as the distance from the zero level, where the transducer is located, to the liquid surface.

What is an advantage of a hydrostatic level?

-

high reliability

-

high accuracy level monitoring

-

direct contact with the medium

-

measurement processes are not affected by factors such as contamination, foam etc. – suitable for foaming or vessel installations

Water level pressure transducers – additional features

Level pressure transducer make it possible to measure not only the current level value, but also to monitor changes in level from an arbitrary reference point within the medium (continuous liquid level monitoring).

What is more, because submersible hydrostatic level transmitter is mounted below the surface of the water, they are totally unaffected by any disturbance to the water surface, such as flooding.

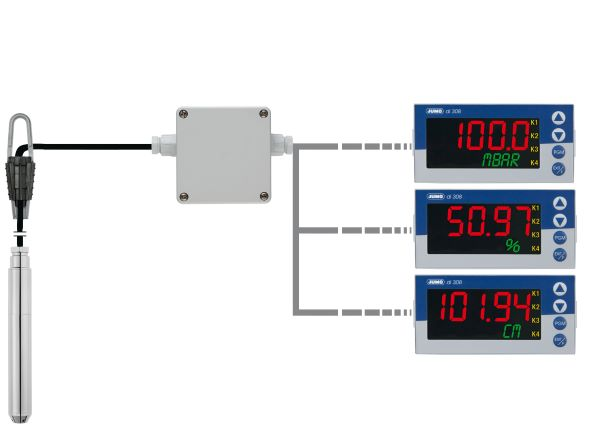

Connection diagram for measurement result display devices

How do I choose the right pressure liquid level sensor?

For open tanks, such as vent vessels, wells or natural or artificial water reservoirs, use submersible pressure transmitters called level probes. For closed tanks, submersible pressure sensors with a flush diaphragm or transmitters that can be screwed onto the tank from the outside will be most suitable.

Once you have made this decision, identify these few key features:

-

pressure connection (only if it is a standard side-mounted transducer) – to fit the threaded hole in the tank.

-

measuring range – this should be selected to suit the level to be measured in the application. In the case of a free-standing tank, the level is determined by its height. In an underground tank, you need to decide at what depth you want to immerse the level probe and select the appropriate measuring range. Note that 10 metres of water column corresponds to a pressure of approximately 1,000 mbar (1 bar) or 14.5 psi.

-

accuracy – a standard accuracy of <0.5% gives a possible error of max. 5 mm per metre of level, while variants with the highest accuracy of <0.1% will have an accuracy of max. 1 mm per metre of level.

-

electrical connection – in a standard sensor you can choose either a connector (such as M12 or DIN A) or a cable outlet, whereas if you have chosen a submersible water pressure sensor, only a cable is an available option.

In the case of a cable connector, you will need to select the correct length to allow the cable from the transducer to the control system and, in the case of a submersible sensor, to be at the correct depth.

-

material of construction – as standard, the level sensors are made of stainless steel, such as the JUMO MAERA S 28, however, for demanding media we recommend a resistant liquid level sensor ps made of titanium, e.g. the JUMO MAERA S 29 hydrostatic probe.

-

additional functions, e.g. ex-zone approval, as in the JUMO dTRANS p33 hydrostatic probe.

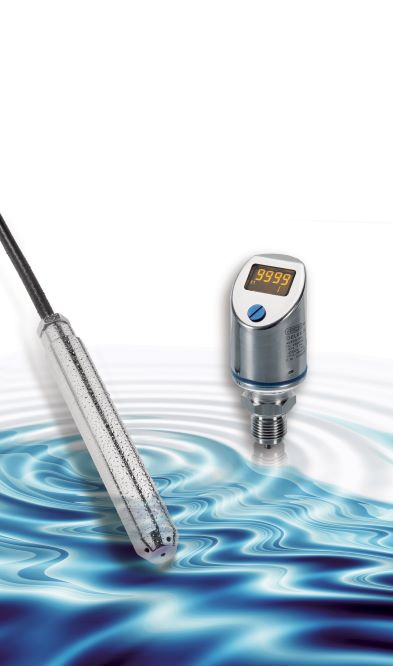

JUMO MAERA S 28 hydrostatic level transmitter in application

Hydrostatic level measurement – temperature compensation

If the temperature of a liquid increases, it will increase in volume, causing the liquid level to rise. This phenomenon has a negative effect on the accuracy of the measurement results. However, if precise hydrostatic level measurement is required at varying fluid temperatures, then, in order to prevent errors due to temperature influence, we recommend fitting a simple and economical additional sensor such as a Pt100 temperature probe.

Alternatively, you can choose a hydrostatic level sensor with an integrated sensor for temperature measurement, such as the JUMO MAERA F27.

Hydrostatic level measurement probe with Pt100 JUMO MAERA F27

What are the available types of cables for a hydrostatic probe?

The available types of cables for a hydrostatic probe like the JUMO MAERA F27 include:

- PUR cable: A grey, polyurethane (PUR) cable, shielded and UV-resistant.

- PE-LD cable: A black, low-density polyethylene (PE-LD) cable, shielded and UV-resistant.

- FEP cable: A black, fluorinated ethylene propylene (FEP) cable, shielded.

What is the maximum length of cable for a hydrostatic probe?

Each of these cables for hydrostatic probes at JUMO is available in various standard lengths, ranging from 5 meters to 100 meters, and can also be tailored to individual customer requirements

JUMO liquid level sensors

JUMO offers a wide range of hydrostatic sensors for the continuous monitoring of liquid levels. Contact us – our specialists will select a device for your application.

Hydrostatische Sonden mit PZH-Zulassung

Die PZH-Zulassung ist ein Zertifikat, das bestätigt, dass eine hydrostatische Sonde den Sicherheits- und Qualitätsstandards für Trinkwasser und die öffentliche Gesundheit entspricht. Dies ist wichtig für Geräte, die im Zusammenhang mit Trinkwasser oder anderen Flüssigkeiten, die die menschliche Gesundheit beeinträchtigen können, eingesetzt werden. Auf Anfrage senden wir Ihnen das aktuelle PZH-Zertifikat für unsere hydrostatischen Sonden zu.

- ${title}${badge}